Address: NO.8 SHIJI ROAD ,LUNJIAO STREET, SHUNDE DISTRICT, FOSHAN CITY,GUANGDONG,CHINA (528308)

TEL:+86-15007571054

FAX:0086-757-26650400

E-MAIL:Sales@vitechgs.com

WEBSITE:http://www.vitechgs.com/

|

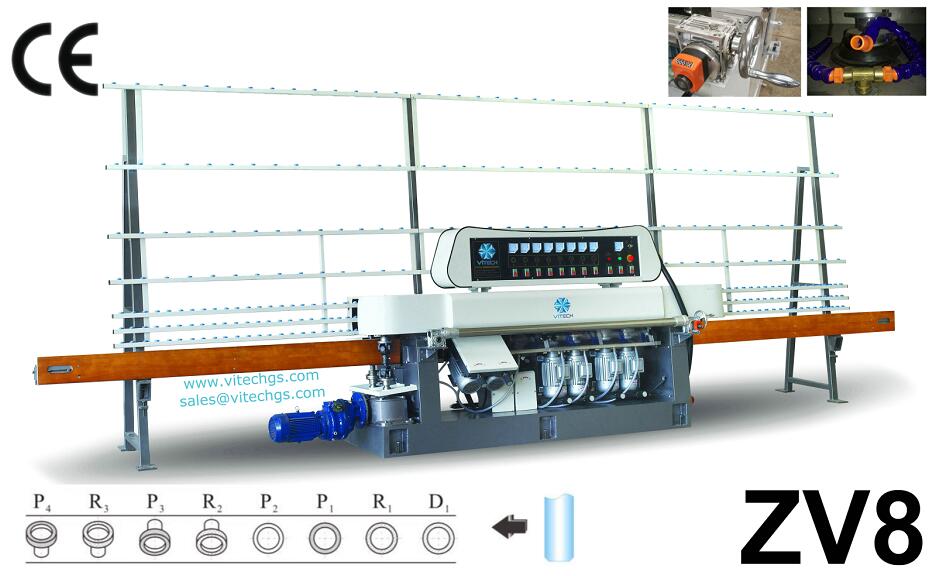

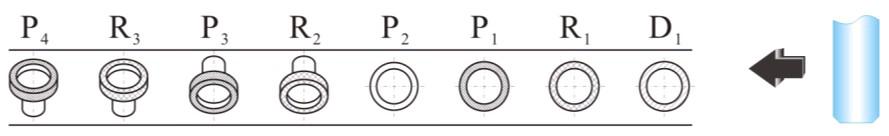

There is totally 8 spindles for VZ8: 4 spindles for the straight-line edge,2 pieces of spindle for front and back arris each.Rough grinding, fine grinding and polishing of the flat edge can be finished at one time. Same thickness of glass sheet can be process continually. The Polishing Glass Sample will be as follow:  1.Brief Introduction 1.1 The ZV8 glass edging machinery is suitable for processing straight-line edge & 45°arrises of glass sheet of various sizes and thicknesses. 1.2 The main base of ZV8 glass edging machinery is made of cast iron. 1.3 The production speed can be adjusted by step-less motor. 1.4 The input and output conveyor adopt timing belt which can improve the transmission precision. 1.5 The glass edging machinery is easy to operate, having good performance. 2. Technical Data 2.1 Processing glass thickness: 3-28mm 2.2 Angle of arris: 45° 2.3 Min.size of glass: 80mm×80mm 2.4 Processing speed: 0.5-4.5m/min 2.5 Installed power: 16.73kw ; 2.6 Occupation of land: : 6600 × 1400 × 2500mm 3. Wheels disposal:

4.Machine Details:

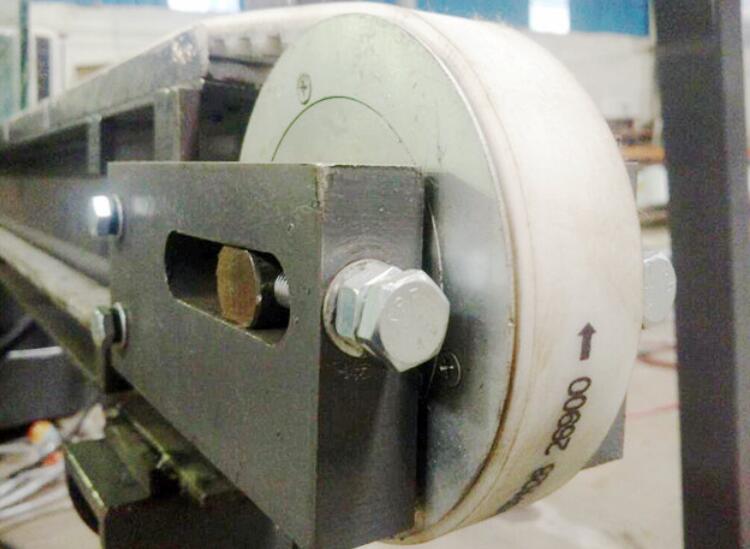

4.1 The spindle with good and stable structure. And it has better waterproof. And the motor with longer service life.   4.2 The large diameter cooling universal water pipe can cool down the glass and the grinding wheels quickly,which can provide the best polishing quality of Glass.    4.5 A special design of the in-feed section for controlling the desired amount of glass removal without adjusting each spindle individually:   5.Option: 5.1 Manual Control:It adopt a hand wheel to adjust the glass thickness, which is suitable for the straight-line edging machine only.  5.2 Digital Display Control:There have digital meter onto the machine panel to adjust the glass thickness. You just need to increase or decrease the parameter you need by the relative switch, then machine can be adjust automatically.  5.3 PLC and Pneumatic Control:Adopt PLC and touch screen, you can input the parameter you need and machine will adjust automatically.  |